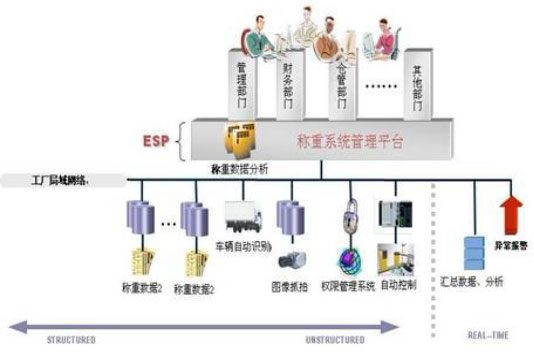

In order to solve the disadvantages of traditional truck scale weighing system, based on the concept of Internet of things, we have developed a smart card unattended intelligent weighing system.

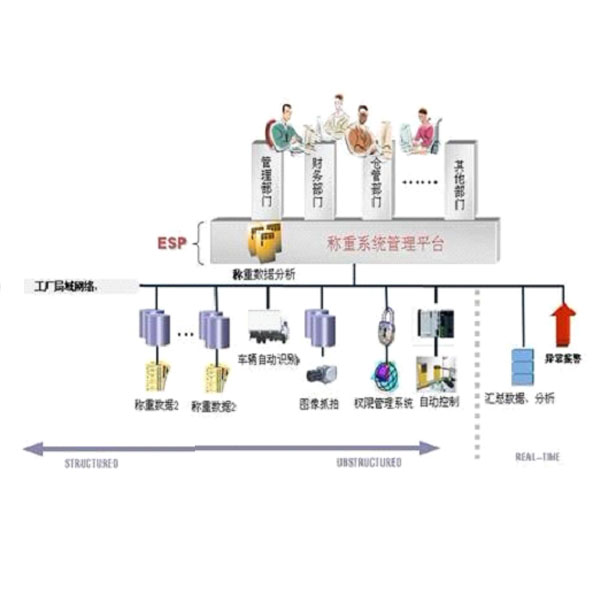

The system uses radio frequency identification (IC/RFID) to complete the authentication of the vehicle; automatic weighing card, vehicle load, vehicle weight analysis of historical data, realize the effective supervision and control of the weighing part material, to prevent cheating, improve the reliability and accuracy of weighing information function. It is an intelligent weighing management system which includes automatic voice command system, weighing image instant capture system, traffic light control system, anti cheat system, gateway control system and remote supervision system. In the whole process of weighing do automatic data collection, automatic identification of reliable heavy fur and automatic control, automatic processing, automatic control, to maximize the reduction of the evils of manual operation and the work intensity, improve the system of information and automation. For the management, can understand the current status of production and logistics through the report summary system; the financial settlement department, you can get a clear and accurate settlement report; warehouse management department can realize their receiving and sending the goods etc.. These data is readily available, so it also strengthens the consistency of management, shorten the response time of decision-makers to production, improve management efficiency, reduce operating costs, promote the enterprise information management.

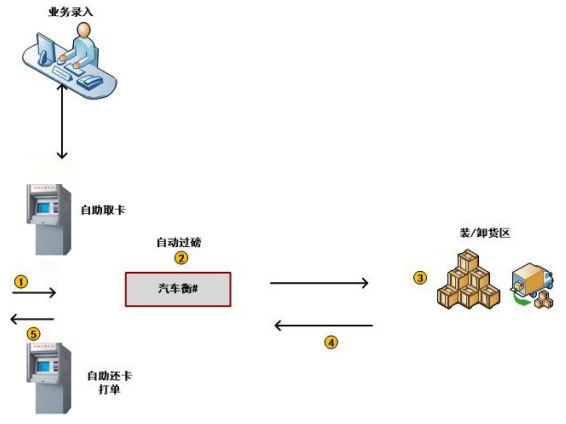

Process description:

The sales department will advance number, goods name, license number, consignee, delivery unit, driver information (name, ID number and other information input system).

1) the driver to the factory to self-service terminal card, input number or brush the two generation ID card, to the corresponding query information, click on the card, the card number and the number will be automatically in the background information related and stored automatically spit out the IC card;

2) driver IC card to carry credit card automatic weighing loadometer;

3) drivers loading and unloading goods at the freight yard;

4) after the completion of loading and unloading, to credit card automatic weighing loadometer;

5) the driver to self-service card terminal, interface display card, weighing the weight of information, click the print, print a single pound, after taking a single system automatic recovery of the card, the driver factory raw materials into the factory process

Process description:

1) raw materials suppliers: issuing according to the delivery notification system of IC card, IC card into the primary information, suppliers, materials, net and number and other information, the automated vehicle card machine;

2) check card into the vehicle parked in the factory: according to the order of inbound channel, IC card in the guard into the factory line outside the process of activation, waiting to enter the factory, the driver (off) brush IC card, RFID IC card verification system through the legitimacy, such as automatically open the gate into the IC card and allows the vehicle to rule system, otherwise the road the brake does not lift rod ban into the vehicle, the vehicle into the factory, to the top of the car without infrared induction automatic drop lever;

3) heavy trucks metering: vehicle to loadometer, infrared positioning system to determine whether the vehicle is completely on the pounds, if not completely on the pounds prompts the driver to adjust the position of the driver (off) in the self-service terminal brush IC card, IC card system to determine the legality of the principle of combination, IC card access IC card information (number, suppliers, raw materials, hair net and arranging order information) if not to forbid, if the IC card metering system, automatic meter reading system data, save data, automatic meter data after capture images, voice and LED screen prompts the vehicle measurement, gross tonnage, please pound to unloading yard;

4) yard receipt: vehicle into the yard, the driver to produce a metering IC card, receipt of confirmation of receipt by holding PDA, and does not meet the acceptance criteria of goods buckle operation, and the consignee, delivery time, goods yard (GPS positioning), buckle information and service state markers write the delivery card;

5) light measurement: after completion of unloading of vehicles pulled out to loadometer, similar to the measurement process of heavy vehicle measurement, the difference is that the severity of the measurement is completed;

6) receiving card: vehicle factory to factory gate channel, brush IC card, verify whether the vehicle door complete business vehicle has complete business open the gate, the release of the vehicle, and the recovery of IC card.

system composition

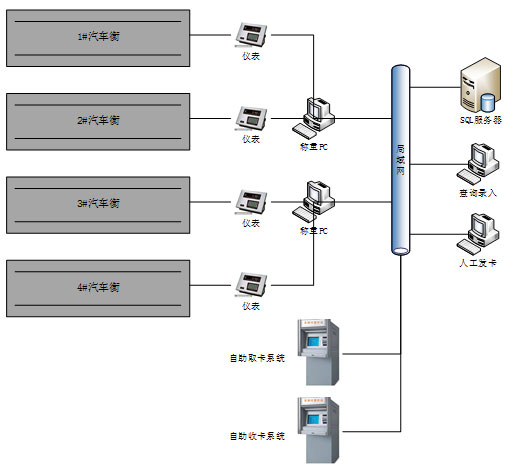

The smart card weighing management system of this project consists of the following three parts:

1) self-help card issuing system

2) unmanned intelligent weighing system

3) data centralized management system

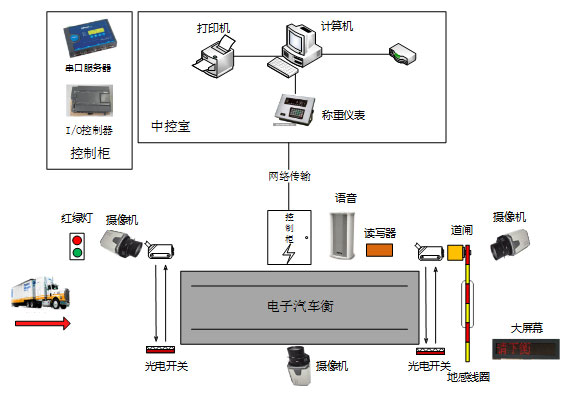

Among them, unattended smart weighing system is divided into the following subsystems:

-

- Digital electronic truck scale subsystem

- Photoelectric sensing subsystem

- Image capture and video surveillance subsystem

- IC card automatic identification subsystem

- LED information indicator subsystem

- Traffic light gate control subsystem

- Speech subsystem

- Weighing management subsystem of upper computer

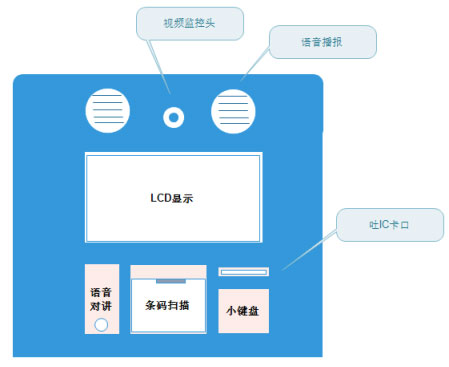

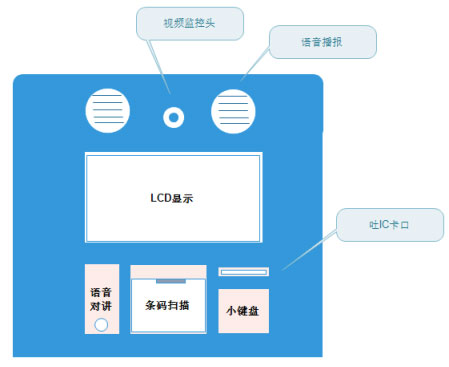

Design of self-help card issuing system

This project requires intelligent design for the transceiver IC card, the sales department will advance number, goods name, license number, consignee, delivery units information input system. The driver to the factory when the first one channel into the outdoor cabinet, enter the two generation ID card number or brush card self-service, the card will be the driver needs to transport cargo information into the card. In the follow-up logistics node operation, it is not necessary to obtain relevant information through network transmission. When the driver leaves the factory, he first goes to the outdoor cabinet on the way out. The IC card is inserted into the card slot to automatically receive the card, and the system reads the information in the IC card and prints the corresponding pound sheet automatically. Through the use of integrated cabinet, the intelligent requirements of unattended access and remote monitoring are realized.

Design of self-service machine

In order to realize the function and performance requirements of the whole machine, firstly, the wide temperature equipment is adopted in the selection of equipment, so as to ensure the normal operation of all the equipment under high temperature. Secondly, all devices use serial ports and convert them into network ports for integrated scheduling, so as to facilitate future program upgrades and extensions. As an independent system, the system interacts with each other through the network and the external large-scale integration system, and receives the scheduling information of the large integration system, and the completed services are fed back to the large integrated system.

Standard specification: 600*800*1850 (unit: mm) see map; material uses 2.0mm cold rolled steel box; surface treatment: anti rust, corrosion, wear and contamination is not easy to damage; the internal structure of the orbit module positioning before and after tractor, the standard wiring neat; exterior structure: configuration of lights, lights, camera to see the data in lights and ventilation equipment. The components and modules are closely linked with the cabinet. The layout is reasonable and the process is fine.

Equipment composition:

IC card reader, to achieve the IC card reading and writing function

ID card identification, the realization of the two generation ID card reading function

The IC card issuing machine, automatic card giving function

The card collector realizes the automatic card receiving function of the IC card

Small keyboard, digital password input operation

LCD screen, the realization of interactive information display

Voice broadcast, the realization of voice prompts

Video surveillance head, the realization of the driver's operation segmentation video, and stored to the server

Small ticket printer, to achieve automatic printing of pound sheets and certificates

Voice intercom and voice interaction between management centerEmbedded industrial computer, integrated linkage front end all equipment

Panel design: schematic (inlet)

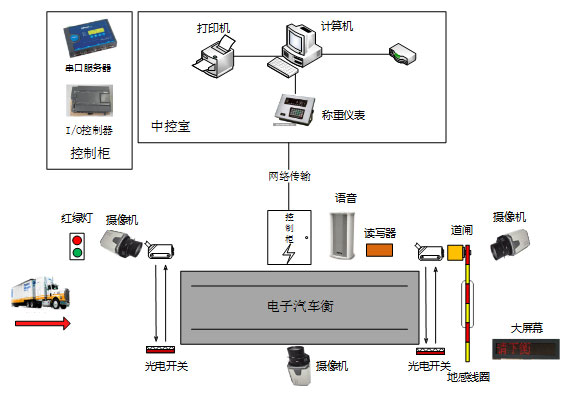

Overview of unattended intelligent weighing system

- The traffic lights: the normal vehicle weighing, prevent the wrong vehicle interference with normal weighing pounds;

- Ground inductance coil: automatic trigger lever;

- Road brake: realize one car and one shot;

- Reader: credit card recognition, vehicle information;

- The electronic truck scale: static weighing loadometer;

- The camera: the front of the rear car monitor and capture;

- The large screen display: weight information;

- The electronic weighing instrument: digital weighing instrument, static weighing truck scale meet the demand; (if in the control room far distance truck scale, taking into account the instrument placed in the scene in the control cabinet)

- Universal printer: printer;

- The hard disk video recorder, video surveillance;

- Electrical control cabinet: imported electrical components, including I/O controller, serial port server, convert equipment related signal for the network signal, through the Ethernet transmission to the hostcomputer;

- Control computer: DELL commercial computer;

- Photoelectric switch: on vehicle positioning, anti cheating;

- Voice equipment: unattended, if there is a problem the driver can talk with the remote control room.