Features & Benefits

Features & Benefits

Strong adaptability

WORKABOUT PRO 3's hardware expansion slots make it easy and fast to add new modules - saving a lot of time and money. And a large number of optional modules - from fingerprint scanning, passport identification to RFID readers and so on.

WIFI, GPRS, Scan Head, Image Recognition and RFID Options - WORKABOUT PRO 3 offers a new generation of modular technology that allows customers to easily configure devices that fulfill multiple tasks for multiple applications.

Insert, tighten the screws, more functions can be used. There is no need to purchase new logical devices because of changing business requirements. Users can replace or add the appropriate module to make it more practical.

Born for movement

WORKABOUT PRO 3's Natural Task Support helps mobile workers work more efficiently and comfortably.

It features a full VGA color touch screen with fine, easy-to-read display, and ergonomically designed, one-handed design.

Extraordinary ruggedness

WORKABOUT PRO 3 can work anywhere you need to work. It uses technology to ensure it is strong enough. Can withstand a number of drops from 1.8 meters to the concrete floor, and can calmly deal with a variety of shock and shock. IP65 degree of protection.

Four communication charge seat

With four-seat communication charger, it can charge 4 WORKABOUT PRO 3 and provide 10 / 100BaseT Ethernet communication at the same time.

Desktop charging cradle

WORKABOUT PRO 3 with all the different configurations is supported. It also provides USB Host and Client interfaces. With a separate battery charging slot.

4 battery chargers

Supports both standard-capacity and high-capacity batteries.

Gun Shank - Various options

Grips can be easily converted to WORKABOUT PRO 3 gun-type equipment.

Top cover - multiple options

12V for car communication dock slot

9V-20V DC power supply. Supports quick plug-in of WORKABOUT PRO 3 and securely fixed WORKABOUT PRO 3. Logic is also available without power supply model of the bracket.

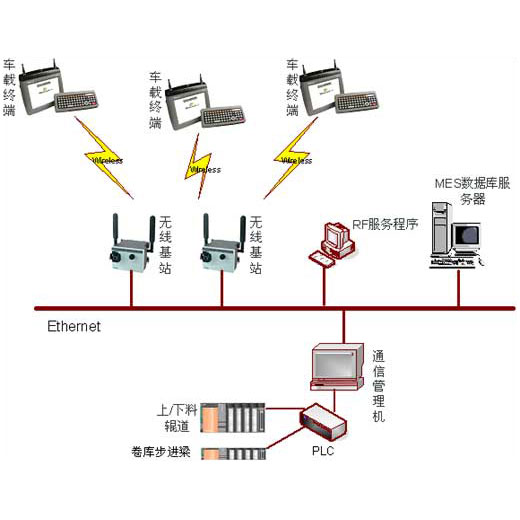

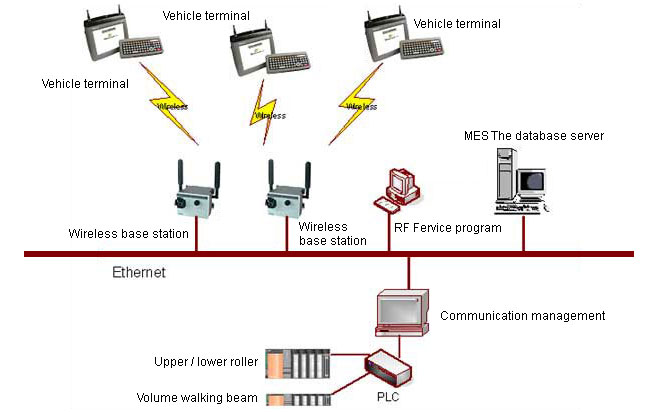

Solution -> Steel Industry Mobile Application Solution

Through the wireless car terminal and handheld terminals, and MES real-time data transmission, combined with bar code and RFID technology to achieve the work of the mobile site operations, effectively improve production efficiency.

The current steel industry is facing the production and business environment is changing, iron and steel enterprises will face fierce competition in the market. In order to reduce inventory, cost savings, the most effective operational strategy is to predict the traditional thrust of the push system to demand plan for the main axis of the pull system, this production model, the enterprise's sales department, production planning department Have put forward higher requirements.

For the steel industry's information requirements, the node-company can provide multi-faceted solutions, including:

• Wireless warehouse management system

For the semi-finished products, finished goods warehouse and spare parts warehouse, through the bar code and electronic tags, to achieve the day-to-day operations of the Treasury automatic data collection and on-site data processing, real-time stacking management, volume, automatic collection, and steel Factory MES system or ERP system interface connection, to provide timely and effective data.

• Crane positioning and wireless operating system

The car terminal is configured in the cab of the crane, and connected directly to the MES system through the wireless network. The crane can obtain the operation task in real time and locate the x, y and z axes during the operation to assist the driver to carry on the correct operation.

• Material field wireless networking

It provides wireless real-time network solution for stock yard. It can remotely monitor and control the reclaimer and unloader. Only need to set up a wireless base station to realize wireless network connection of all material yard, and realize real-time monitoring.

• Vehicle management

The use of RFID to achieve access to the steel plant and effective management of vehicles, vehicles into the factory after the jin, sampling, sample preparation, unloading, re-skinning and other aspects of management, the staff can use handheld terminals at any time to read RFID cards And the read information is transmitted to the data center in real time to provide the management means for the route, flow and time after the vehicle enters the factory, so as to improve the level of vehicle management by the steel mills.

Enterprise wireless warehouse management system

How can a decision maker get the last minute of data in a company with several buildings and thousands of employees as a small city? And in accordance with the latest data quickly make the right judgments in time to respond to those who are even the most critical of the special requirements of customers in order to maintain business competition.

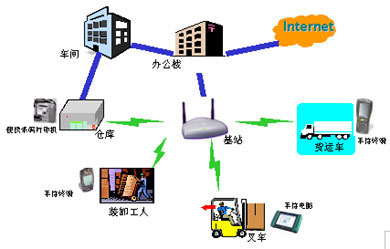

What is Wireless Warehouse Management System

Wireless storage management system based on RF technology Relying on the existing management system, the RF technology, bar code technology and wireless computer network technology are combined to integrate the advanced hardware and software systems, focusing on the site of the data warehouse, from Fundamentally to ensure the actual operation, logistics and background database at any time three areas of accurate uniform, while further improving the operational efficiency, and truly achieve the scientific management of the Treasury

1. First of all, it provides a space-free information application environment, so that even within the enterprise and even outside the exchange of information possible. Have proven very suitable places such as three-dimensional warehouse into the library, the production line and the completion of complex environmental areas such as packaging.

Second, the use of wireless communication equipment to set up wireless LAN, through the programmable mobile computing terminal "into the network" work for the popularization and use of bar code technology to provide a platform to help enterprises to achieve information standardization and rapid logistics management. (Our country has strongly promoted the application of enterprise product bar code technology, which is the basis for international companies to one of the conditions) and bar code technology, the development of enterprise resource management extension to improve the system response speed for customers with high quality services, And provide real-time and accurate decision-making reference data for managers.

In addition, more mature information technology development of the enterprise, you can also make full use of existing ERP information resources, with the wireless network of flexible means of mobility.

Technical solutions

Wireless network, communication technology (with ERP system or inventory management system) and bar code technology is the wireless warehouse management system technology assembly.

wireless network

Wireless base stations based on the IEEE 802.11b standard for wireless LANs can be interconnected with any standard-compliant device and can cover all corners of the enterprise campus, whether in the office, factory, warehouse, or yard. Real-time data transmission through the mobile terminal.

Based on the public network GRPS / CDPD / CDMA wireless network technology allows you to any field in the enterprise warehouse, store or freight car, and the headquarters of the data center can be real-time query and data exchange, real-time data updates.

Communication Technology

Communication technology for handheld devices to provide ERP system or inventory management system data interface to complete the two-way data transmission, handheld devices to achieve real-time data on-site data collection and real-time transmission.

Bar code technology

Bar codes can be used not only in the enterprise's products, can also be applied to various areas of internal management of enterprises to speed up the data entry level and accuracy.

In the full analysis of business processes on the basis of identifying information-intensive, the formation of bottlenecks in the information link, the timely introduction of bar codes.

How should companies use this new technology?

A. Correctly understand the technical characteristics of wireless storage systems

B. Confirmed that the relationship between information management, information display and information transmission has been understood, and the introduction and update strategy should be rationally formulated according to the current situation of enterprise informatization development.

C. Focus on the production, supply and marketing of this core throughout the operation of the enterprise line (the basis of the supply chain structure) analysis, identify the information processing bottlenecks are not suited to list all possible solutions, summary of the need for mobile processing, Real-time processing and accurate processing of data points of demand, and then according to demand analysis of the overall plan for the implementation of wireless networks

D. For enterprises that have implemented and used the ERP system, they need to consult with the suppliers and service providers of the ERP system to obtain the original data structure of the manufacturer, and then identify the data acquisition points that need to be improved. Wireless collection mode function, and then develop a re-development program. It should be noted that different ERP systems, the scope of application differences and the level of management will introduce the wireless network technology have a different impact.

The advantages of wireless-based warehousing systems

1. Accuracy is close to 100%

A) Each operation must be verified for execution, eliminating the risk of errors and the resulting costs

2. Reduce labor costs

A) Warehouse operators do not have to spend time searching for goods

B) No manual input of large amounts of data

3. To improve customer service quality

A) Real-time control of order status

B) Eliminate order delay

4. Reduce inventory

A) The goods entering the warehouse can appear on the sales list

B) Eliminate excess inventory to ensure safe stock

C) reduction of inventory write-off