The fixed-value loading system can quantitatively control the loading of powdery and granular materials such as bulk cement. It combines weighing, automatic control, video surveillance and other technologies in one, to prevent the vehicle weighing cheating, widely used in the cement industry.

In the bulk cement sales process, the traditional manual operation often appears more or less loaded equipment phenomenon, resulting in repeated invoicing and measurement, low efficiency, high cost, because the feed can not control how much, often overflowing material, resulting in serious waste of cement And environmental pollution. In order to reduce economic losses, cost savings, improve work efficiency, fixed-value loading, to avoid overloading and improve management level. I independently developed and successfully launched a fixed value cement loading system for many users in the bulk cement production and marketing process to solve the practical problems.

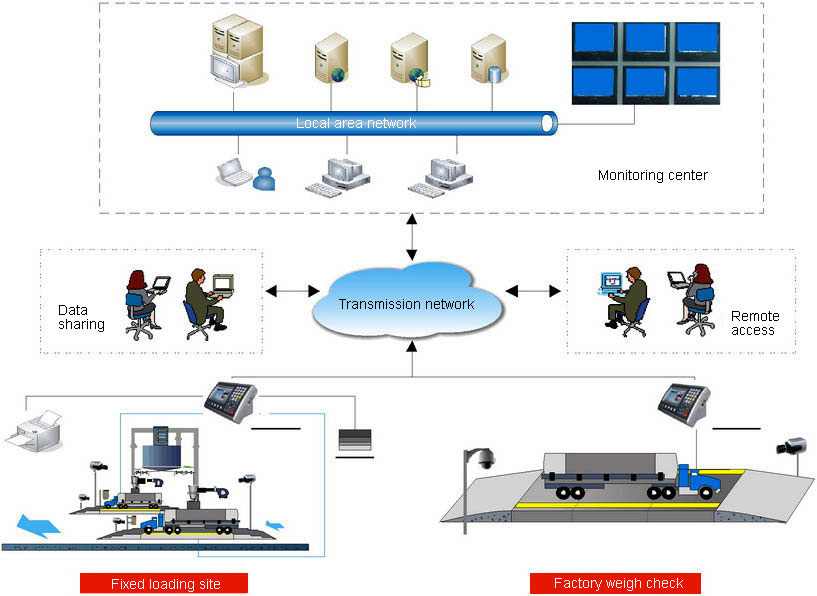

Topology

System functions

> Bulk metering, pneumatic filling, cost savings

> Automatic filling operation, print pounds of single

> Loading mode flexible, multi-level control, high accuracy

> Real-time display loading weight, intuitive and reliable process

> Loading data is true, to prevent artificial cheating

> Automatic, manual loading can be arbitrarily switched

> Loading process controlled to avoid overflow or less installed

> System integration is high, easy maintenance

> Data sharing, real-time understanding of shipments

> Seamless connection with ERP for easy financial management

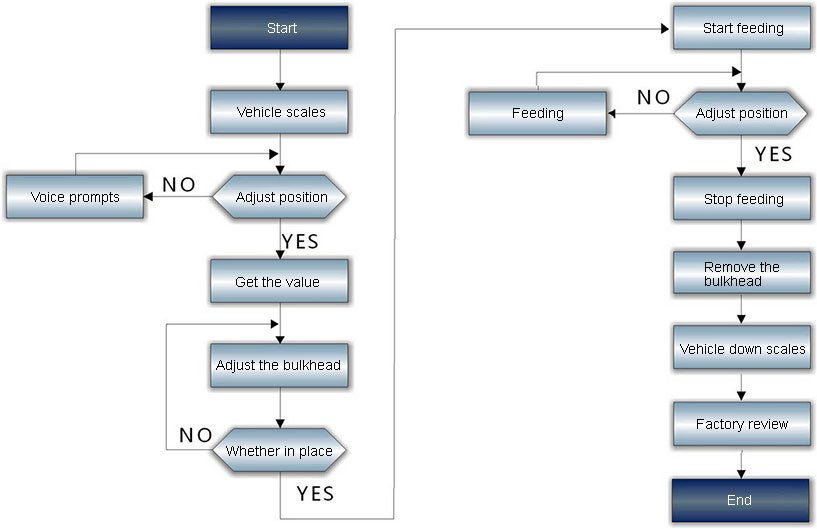

Flow chart